Ha q x A kN A. Q 2 kNm² for varnished timber mould.

Technical Drawing Of Hook Number 12 Download Scientific Diagram

Let us assume a.

. First separate the object into rectangles and then calculate the weight of each section individually and then combine them as shown below. Tension on Sling T 1 2 V1 2 H1 2 12 Tension on Sling T 1 2 W legs sin a 1 2. Dynamic Impact factor Fh fSQRTfxfx2fyfy2fx2 Iy2db223b312.

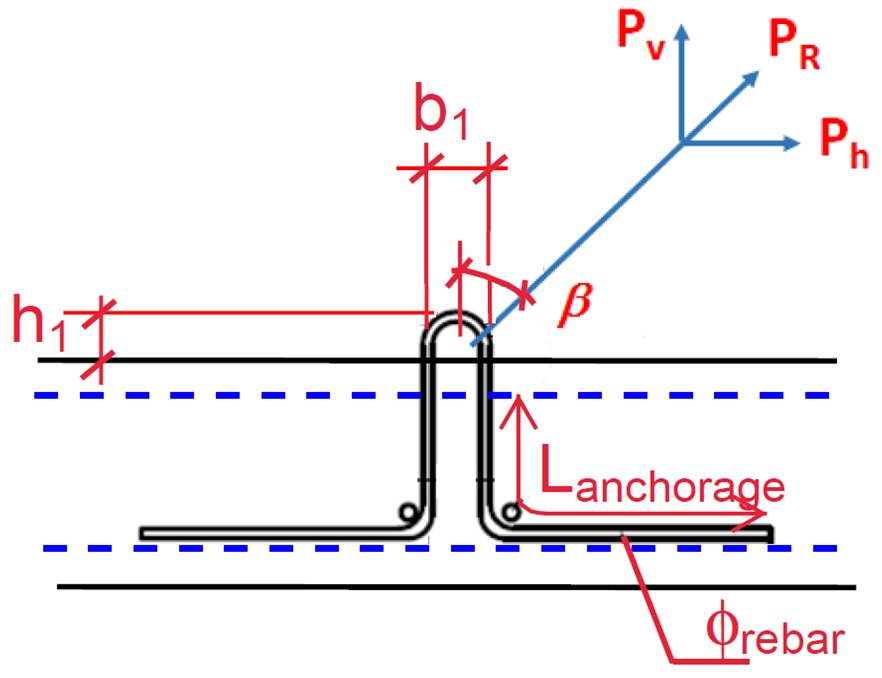

F1min Gconc 2 Gsteel a1 b 1 p F1min 1101 2 033 183 366 1 20 F1min 454kN Second lifting hook maximum effort. Ricker originally published in American Institute of Steel Construction AISC - Design Journal 4th Quarter 1991. Minimum anchorage length provided Le assume 90 0 bend 1000 mm.

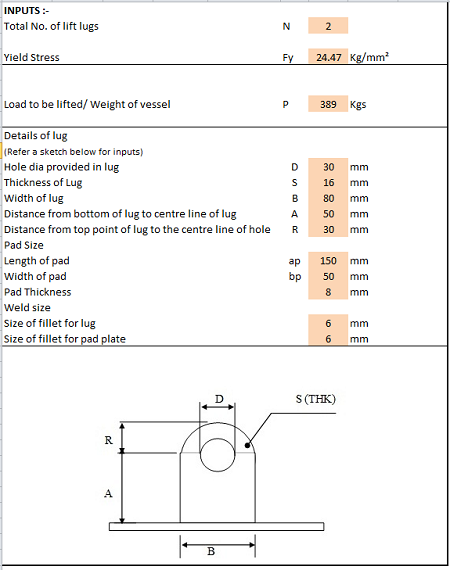

Free delivery available on over 600000 products at RS Components. A lifting hook is a device for grabbing and lifting loads by means of a device such as a hoist or crane. Volume 1 Top 4 feet x 2 feet x 3 feet.

115 min1ξmax1ξV L. For producing a safe reliable design This is the most widely used lifting lug design standard. Al 2009 this paper presents the different methods of stress calculation for lifting hooks based on different assumptions.

F2max Gconc 2 Gsteel a2 b γdyn γα 1 p F2max 1101 2 033 183 366 16 10086 1 20 F2max 1099kN. Max 1 xi cdot V_ L. Q 1 kNm² for oiled steel mould.

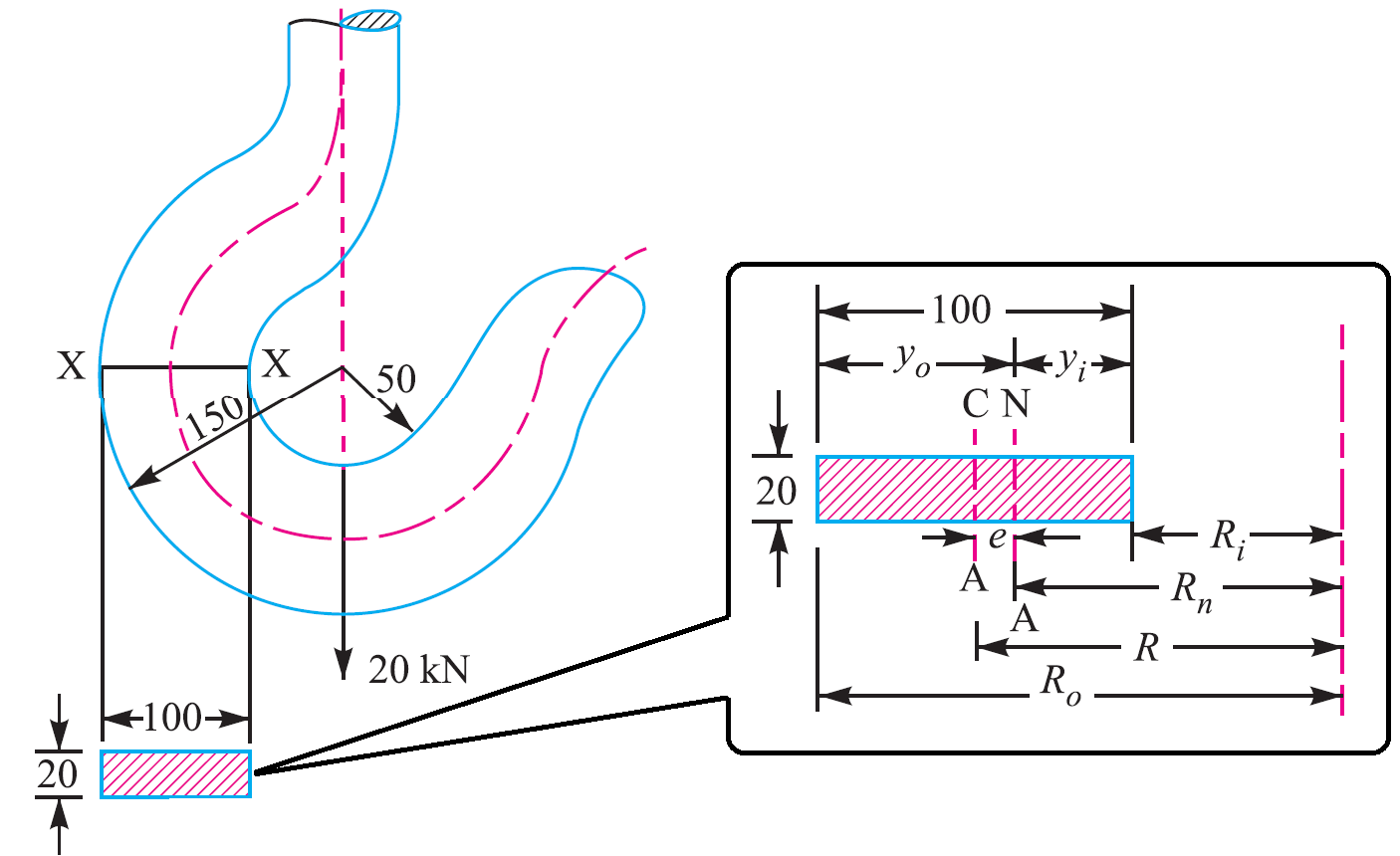

Section X-X height h 100 mm. A lifting hook is usually equipped with a safety latch to prevent the disengagement of the. 3C the sling lengths can be calculated using the following formulae.

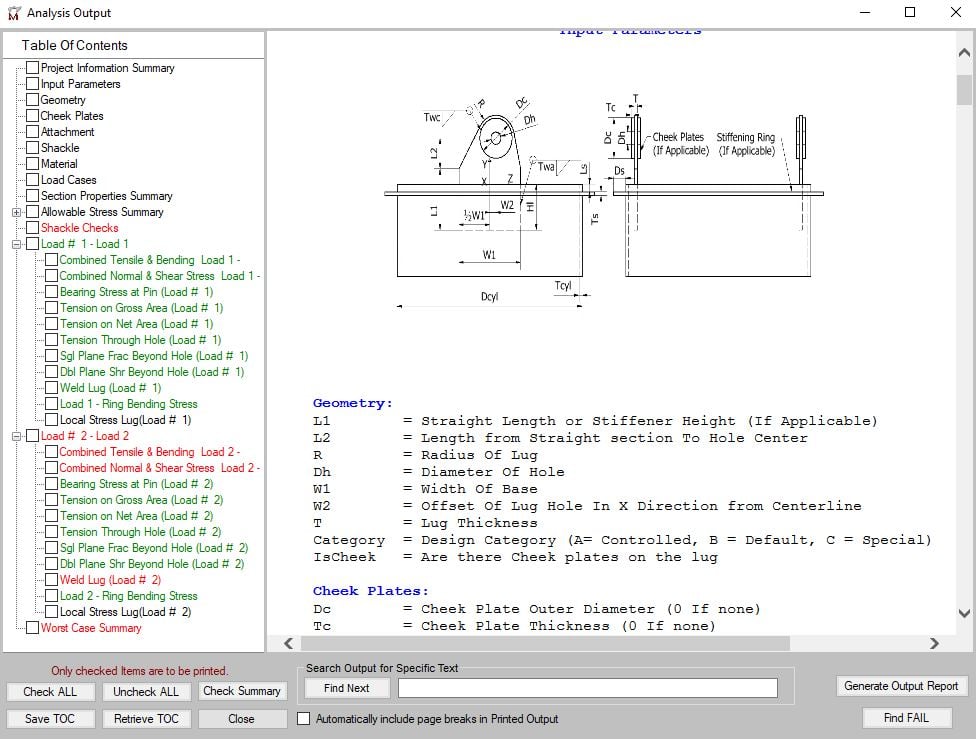

Anchorage length required L of each bar DL Dia Fbu 41336 mm Le 1000 mm Page 4 of 16. I found the BTH-1-2008 publication commentary sections very usefull. The design of below-the-hook lifting devices are standardized in the United States by ASME B3020 and further detailed in Below-the-Hook Lifting BTH-1-2008 Design of Below-the-Hook Lifting Devices.

Forged Steel Wrought Iron. Section X-X breadth b 20 mm. Q 3 kNm² for rough timber mould.

Dynamic factor. ASME BTH-1 specifies design calculations for different types of loading of a lifting device including tension compression flexure shear and combined loading of beams. Dynamic Amplification Factors Fh for LIGHT Packages.

Using the design calculation from the modeling the analysis of hook is done in FEA software This result lead us to the determination of stress in existing model. 2 Design of C-hook. By predicting the stress concentration area the hook working life increase and reduce the failure stress.

BDesign of Below-the-Hook Lifting Devices - ASME BTH-1-2008 American Society of Mechanical Engineers. INTRODUCTION Crane hooks are highly liable. Min 1 ξ.

Heres how you would calculate the load weight of an irregular shaped object made out of concrete. Volume 1 24 cubic feet. Often the pin diameter is much less than the hole diameter.

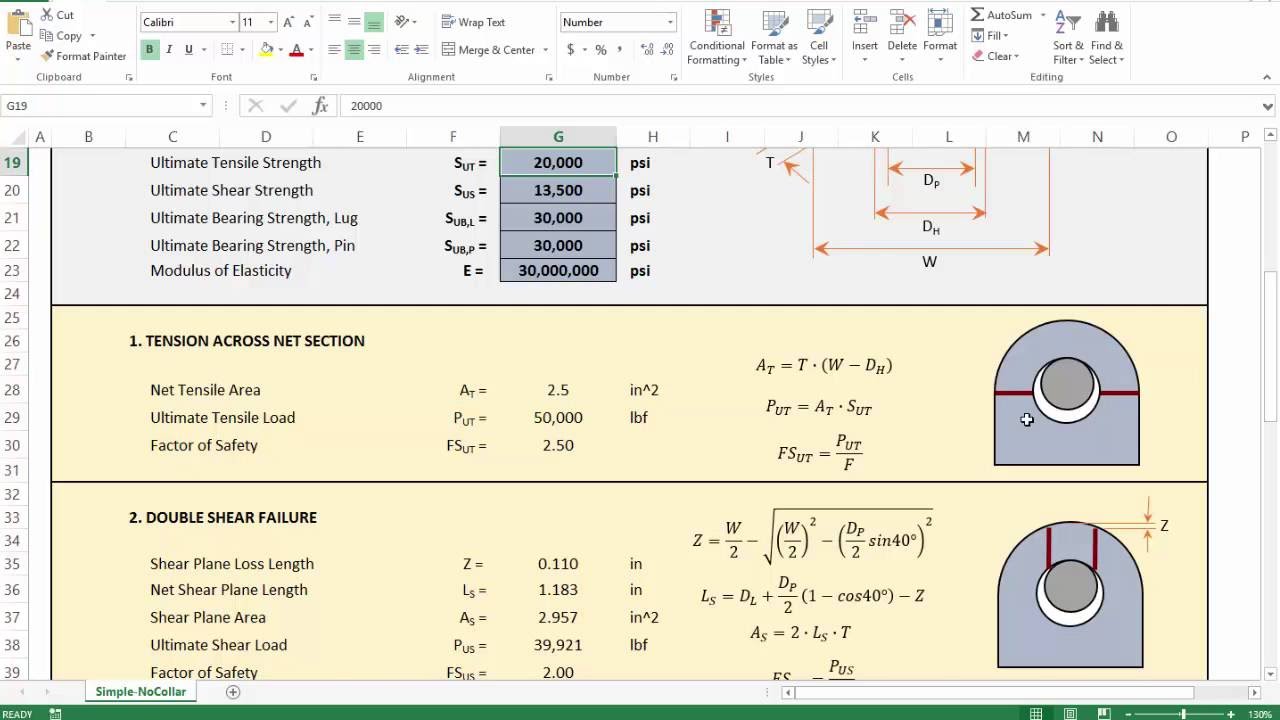

DesignEvalution of Overhead Lifting Lugs Page 2 Pw2 16875kip Pw2 09Fytdpin 18 dpin d 050 in This failure mode involves bearing failure at the pinlifting lug interface. However As such standards do not clearly address the local stress calculation steps Finite Element Analysis is performed using various. The quantity of effective lifting points may be less than the quantity of real lifting points if the system is not balanced.

The distance between neutral axis to the outside fibre Y o R o R n. 2 a H Ha. The lifting hooks can be classified into the single hook.

Formwork adhesion Ha is calculated through the following equation. Depending on the style of lifting device only certain structural. 1 5 min 1 xi.

I did not find the David T. To attach the load locate the center of gravity position the crane hook directly above the center of gravity and then rig the load so that it will lift level and true. Calculations to be made will include the capacity both of the overall beam and of the loading of the individual lifting points.

Area of this rectangular section X-X A Breadth b x Height h 20100 2000 mm². ASME BTH-1 Design of Below-The-Hook Lifting Devices governs the design of lifting lugs for industries. ADesign and Construction of Lifting Beams - David T.

1 a H Ha. 115 with ξ 03 for fixed crane or on rails and ξ 06 for crane bridge. By varying the lengths of chokers a fixed-tilt lifting beam can be made as depicted in Fig.

Area of contact between the mould and the concrete unit when starting to lift. Calculations were performed to the thermal expansion stress using finite element analysis such as linear. Bending stress in curved Beams This Crane hook is considered as the initially curved beam.

They applied curved beam theory Finite Element Method and photo elasticity experiments to obtain the stress field on the hook. FDESIGN FOR ADEQUACY OF PROVISION OF SINGLE LIFTING HOOKS. Ad Free delivery available on Lifting Hooks.

Max 1 ξ V L. Diameter used Dia 953 mm. Another important consideration is the centre of gravity of the load to be lifted together with any accessories and or attachments used - slings grabs shackles hooks magnets vacuum pads etc.

First lifting hook minimum effort. 2 2 2 sinq long sling length. As a result different methods used to obtain the stress field on.

Expressed in terms of variables noted in Fig.

Crane Hook Design Problem Sample Extrudesign

Lifting Lug Design Mecalug Software Meca Enterprises Inc

Lifting Lug Design With Example What Is Piping

0 comments

Post a Comment